INTRO

Do you have a great new project idea or do you need help in a specific area? Our team of Engineers like to turn complex dynamics into the simplest possible solution. You will profit from low production costs, easier sourcing due to standard parts allowing you to scale your production. From stress calculations to thermal simulations, from idiation to industrialized product, we are here to support.

Expertise

Sheet Metal Design and Construction

Load and Stress Calculations

Efficiency Optimizations

Machine Redesign and Upgrade

Material Selection Consultation

CAD Design and Modelling

Rapid Prototyping

BoM Analysis and Cost Reduction

Heat Transfer Simulations

Tolerance Analysis

Assembly and Maintenance Planning

Safety and Compliance Checks

Retrofitting

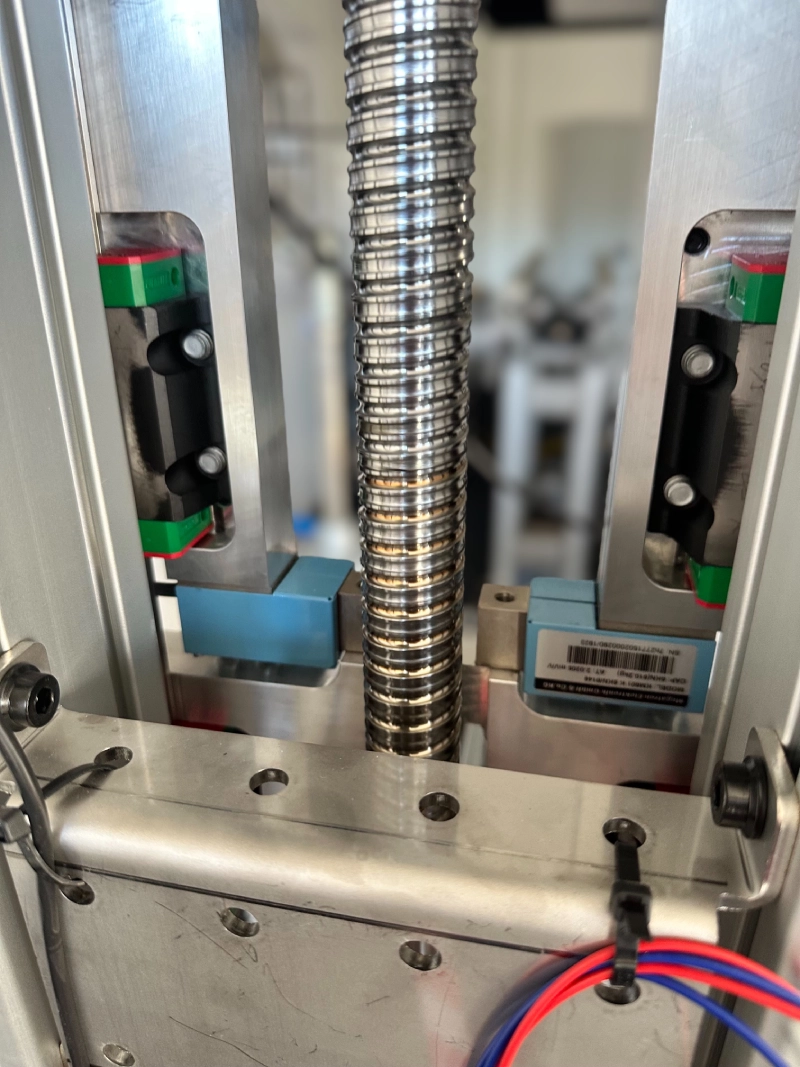

Mechatronics

Concept

First of all, we create a joint concept. We are dependent on you for this. Nobody but you knows your subject area and your wishes as well as you do. We need a specification sheet from you with all the requirements so that we can derive our project specifications from it, make you an quote and work out a schedule together. If you wish we can create the specification sheet together with you as part of the project.

Product development

We divide the development into structured packages. We call these phases. Each phase ends with an agreed work product. This means you have full control over the development process and you are constantly involved. Once one phase is complete, the next begins.

We start with workshops to come up with ideas for technical sub-functions and test these using rapid prototyping in so-called functional models. These give you confidence. You will soon receive a proof of concept prototype from us that works, but looks very different from the end product.

SIMULATIONS

Where necessary, we use simulations to ensure safe and reliable operation later on. This enables us to run through various scenarios in advance.

Testing

We live by the motto "What hasn't been tested doesn't work". Your device is put through rigorous testing to ensure that there are no unexpected failures once on the market. Because this topic is so important, we have dedicated an entire page to it.

Certification

We help you research standards and find the relevant points. If necessary, we can put you in touch with external testing bodies such as TÜV and provide you with the necessary documents.